Request a quote

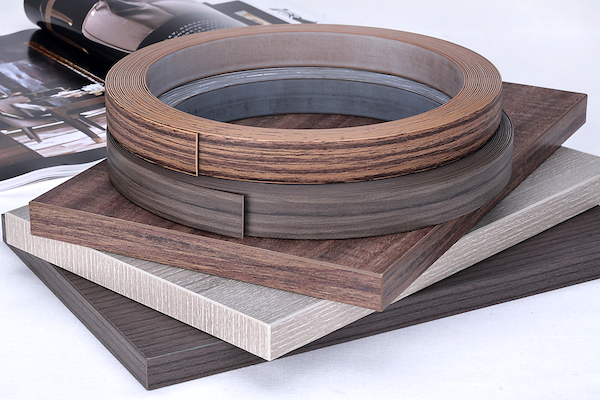

The manufacturing process of PVC edge banding typically involves the following steps:

1、Extrusion of Base Material: PVC material is processed into the base material of the edge banding through an extrusion machine, which serves as the foundational material for the edge banding.

2、Embossing: Applying a certain level of pressure and temperature to create the desired texture or pattern on the base material. This helps the edge banding better mimic wood grain or other textures.

3、Surface Printing: Depending on requirements, patterns, colors, or decorations can be printed on the surface of the edge banding to meet various design needs.

4、Hot Melt Adhesion: Using hot melt adhesive on a semi-automatic or automatic edge banding machine to affix the PVC edge banding to the edges of the board. Fusion typically occurs within a temperature range of 140 to 220 degrees Celsius to ensure a secure bond between the edge banding and the board.

5、Cutting: The long strips of PVC edge banding material are cut into the required lengths to suit specific applications.

6、Packaging: Finally, the edge banding is packaged into rolls or other suitable forms for transportation and sale.

Through the aforementioned manufacturing process, PVC edge banding is produced to play a crucial role in the realms of decoration and furniture manufacturing, offering an aesthetically pleasing, durable, and easy-to-install edge sealing solution.

Specification List

| Ltem | Range | Tolerancerange |

|---|---|---|

| Width | 12mm——20mm | ± 0.5mm |

| 21mm——54mm | - 0.2mm, + 0.8mm | |

| Thickness | 0.4mm——0.7mm | ± 0.05mm |

| 0.8mm——1.5mm | ± 0.1mm | |

| 1.6mm——2.0mm | ± 0.15mm | |

| 2.1mm——3.0mm | ± 0.2mm | |

| Surface gloss | 5——30∘ | -3∘ , +5∘ |

| 31∼90∘ | -3∘ , +5∘ | |

| Meters\Roll | ≤100m | ± 0.5m |

| 100m——300m | ± 0.8m |